Choosing The Right Cold Chain Management Solution

Effective cold chain management is crucial for global trade. It’s about ensuring products that need to stay cold, like vaccines and fresh food, stay safe throughout the supply chain.

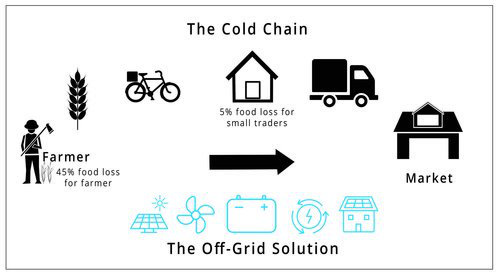

Managing the cold chain in global trade is tough. It’s not just about moving stuff; it’s about keeping it safe. The cold chain is a refrigerated transport system and careful handling that protects goods from temperature changes. It’s crucial for businesses that rely on freshness and quality.

It’s complicated because many things can go wrong from start to finish. If something goes bad during the journey, it can ruin the product, cost a lot of money, and hurt a company’s reputation.

Having the right cold chain management solution is vital. It’s not just a tool; it’s a must-have for success. Picking the right one can save money, improve tracking, and keep up with rules and regulations.

This article helps you understand what to think about when choosing a cold chain management solution.

The Significance of Effective Cold Chain Management:

Effective cold chain management is crucial for global trade. It’s about ensuring products that need to stay cold, like vaccines and fresh food, stay safe throughout the supply chain.

Keeping products at the right temperature is super important. In food, if things aren’t kept cold, they can spoil, causing big losses for everyone involved and even making people sick.

Good cold chain management helps businesses save money by reducing waste and making sure things run smoothly. Using technology to keep track of temperatures and fix problems before they happen is key.

Understanding the Challenges:

The cold chain is tough to manage because it involves keeping things cold while they’re being transported. It’s especially tricky because even small temperature changes can ruin products.

One big challenge is making sure the temperature stays steady. Weather changes and delays during transport can mess things up. Different factors like where things are being shipped from and how they’re being transported make it even harder to keep things cold.

On top of that, there are lots of rules to follow, especially in industries like healthcare and food. Breaking these rules can have serious consequences, like getting fined or damaging a company’s reputation.

Because cold chain products can go bad quickly, any delays or mistakes can cause big problems. Unlike other shipments, even small issues can cause a chain reaction of problems.

Coordinating with everyone involved in the cold chain, like suppliers and distributors, is also a challenge. If communication breaks down, it can slow everything down and make the process less efficient.

And when it comes to international shipments, there are even more rules and complications to deal with, like customs and different regulations in different countries.

Understanding these challenges is the first step in dealing with them. By using technology and coming up with smart strategies, businesses can reduce risks and make the cold chain work better. There are lots of new ideas out there, like using data to predict problems or using blockchain to track products, that can help make the cold chain easier to manage.

Importance of Choosing the Right Solution:

Picking the right solution is super important. It’s not just about moving things; it’s a big deal for the success of a business.

The right solution keeps products safe and follows the rules. Whether it’s vaccines or food, keeping the right temperature during transport is crucial. A good solution helps track temperatures accurately and reliably.

Choosing the right solution can also save a lot of money and make things run smoother. By keeping temperatures steady and reducing waste, businesses can cut costs and use resources better.

Plus, the right solution gives businesses a clear picture of where their products are and how they’re doing. This helps them make smart decisions and fix problems before they get big.

It’s also important that the solution works well with other systems a business already has. This makes sure everything keeps running smoothly without causing problems.

In a competitive market, having the right cold chain solution can make a business stand out. It helps keep products fresh, safe, and reliable, which builds trust with customers and gives the business an edge.

Basically, choosing the right cold chain solution is about investing in the future of the business. By focusing on product safety, saving money, following rules, and keeping customers happy, a business can grow, innovate, and stay strong in a tough market.

Key Considerations In Selecting a Cold Chain Management Solution:

Picking the right cold chain management solution is a big deal because it can really affect how well your logistics work. Here are some important things to think about when choosing one:

1. Temperature Monitoring: Make sure the solution can keep track of temperatures in real-time. Look for features like wireless sensors and data loggers to get accurate temperature readings.

2. Data Visibility and Analytics: Choose a solution that lets you collect and analyze data so you can make smart decisions. Look for customizable dashboards and predictive analytics to help you understand temperature trends.

3. Integration with Existing Systems: Your new solution should work well with the systems you already have. Make sure it can connect with your ERP and other software smoothly.

4. Scalability and Flexibility: Pick a solution that can grow with your business and adapt to changes. Look for options that can be customized to fit your needs as your business expands.

5. Compliance: It’s important that your solution meets industry standards and regulations. Check that it follows rules like Good Distribution Practices (GDP) and Hazard Analysis and Critical Control Points (HACCP).

Types of Cold Chain Management Solutions:

Businesses have different options to keep their temperature-sensitive products safe. Here are some common types of solutions:

1. Traditional Solutions: These use manual processes like thermometers or data loggers. They’re cheaper but may not offer real-time tracking or advanced features.

2. Digital Solutions: These use modern tech like IoT and data analytics for real-time monitoring. They’re accurate and efficient, reducing the risk of spoilage.

3. Integrated Solutions: These cover everything from production to storage and work with other systems like ERP. They offer comprehensive insights and help streamline operations.

4. Standalone Solutions: These focus only on temperature monitoring and are simple to use. They’re good for smaller businesses or specific needs but may not scale well.

5. Cloud-based Solutions: They store data in the cloud, offering flexibility and accessibility from anywhere. They’re easy to update and maintain but require an internet connection.

6. On-premises Solutions: These are installed locally and offer more control over data. They’re good for industries with strict regulations but may need a big upfront investment.

By knowing these options, businesses can choose the right solution based on their needs and budget. Whether it’s traditional methods or modern tech, the goal is always to keep products safe and high-quality throughout the supply chain.

Evaluating Potential Solutions:

Choosing the right cold chain management solution is a big deal because it affects how well your logistics work. Here are some important things to think about when choosing one:

1. Functionality and Features: Make sure the solution has what you need, like temperature monitoring and data analytics. Look for customizable options that can grow with your business.

2. Reliability and Performance: Check if the solution works well and has a good track record. You might want to test it out or see a demo to be sure.

3. Scalability and Flexibility: Make sure the solution can grow with your business and adapt to changes. Look for options that can be customized and are compatible with future upgrades.

4. Ease of Implementation and Use: Choose a solution that’s easy to set up and use. Look for user-friendly interfaces and good support resources.

5. Cost and ROI: Consider how much the solution will cost and what you’ll get in return. Compare upfront costs with potential savings and benefits.

6. Vendor Reputation and Support: Research the company behind the solution to make sure they’re reliable and have good customer support.

By considering these factors carefully, you can pick a cold chain management solution that fits your needs and helps your business succeed. Make sure to involve everyone who will be using the solution in the decision-making process.

Conclusion:

In the ever-changing world of supply chains, one thing stays the same: the need to keep improving. By using good cold chain management and picking the right solution, businesses can grow and stay strong in a competitive market.

As you deal with cold chain logistics, remember that success comes from using technology, working together, and planning ahead. By choosing the right solution, you can keep your products safe, reduce risks, and make customers happy. Remember to pick the solution that fits your business best.